WhatsApp)

WhatsApp)

Manufacturing Process < About Cement < Cement: Lafarge Lafarge, building better cities. World leader in building materials with topranking positions in Cement, Aggregates, Concrete. Access to the content Access to the ...

Portland cement clinker overview Portland cement clinker is a dark grey nodular material made by heating ground limestone and clay at a temperature of about 1400 C 1500 C. The nodules are ground up to a fine powder to ...

In the manufacture of Portland cement, clinker is the solid material produced by the cement kiln stage that has sintered into lumps or nodules, typically of diameter 325 mm. Clinker, if stored in dry conditions, can be kept for several ...

Chapter 1 Introduction to Cement Production The resultant raw mix is burned in a rotary kiln at temperatures around 4482 degrees Celsius to form clinker, The wet process of fine grinding is the older process, having been used in ...

Cement Manufacturing 277 Air Emissions A maximum emissions level of 50 milligrams per normal cubic meter (mg/Nm 3), equivalent to a maximum of kg/t of clinker, for particulates in stack gases under fullload conditions is to ...

A process for manufacturing a rapid hardening portland cement clinker containing a calcium haloaluminate having the formula; , in which X is a halogen, characterized by adding at least one sulfur compound ...

Manufacturing process < All about Cement < Cement : Lafarge Lafarge, building better cities. World leader in building materials with topranking positions in Cement, Aggregates, Concrete. ... Ensuring a good yield The reliability ...

Portland Cement Manufacturing Process Description17 Portland cement is a fine powder, gray or white in color, that consists of a mixture of hydraulic cement materials comprising primarily calcium silicates, aluminates ...

Manufacturing Process < All About Cement < Cement : Lafarge Lafarge, building better cities. World leader in building materials with topranking positions in Cement, Aggregates, Concrete. Access to the content Access to the ...

Good Practice Guidance and Uncertainty Management in National Greenhouse Gas Inventories CO2 Emissions from Cement Production 179 countries to collect clinker or cement production data from each plant in the country. To ...

IXMaterialsBCement5 together into a mill where the rock is ground until more than 85% of the material is less than 90µm in diameter. The wet process The clay is mixed to a paste in a washmill a tank in which the clay is ...

There are two general processes for producing clinker and cement in India : a dry process and a wet process. The basic differences between these processes are the form in which the raw meal is fed into the kiln, and the amount of ...

Cement Manufacturing Process Phases Production of cement completes after passing of raw materials from the following six phases. These are; Raw material extraction/ Quarry Grinding, Proportioning and Blending Preheater Phase

A typical process of manufacture consists of three stages: grinding a mixture of limestone and clay or shale to make a fine "rawmix" (see Rawmill); heating the rawmix to sintering temperature (up to 1450 C) in a cement kiln; grinding ...

Clinker Steps The following steps demonstrate the chemical reactions, which occur during the forming process of Portland cement clinker. The presence of oxidizing conditions, during the clinker forming reaction, is critical to the ...

The cement manufacturing process starts from the mining of raw materials that are used in cement manufacturing, mainly limestone and clays. A limestone quarry is inside the plant area and a clays quarry is as far from the plant area ...

In the manufacture of Portland cement, clinker occurs as lumps or nodules, usually 3 millimetres ( in) to 25 millimetres ( in) in diameter, produced by sintering (fused together without melting to the point of liquefaction) limestone ...

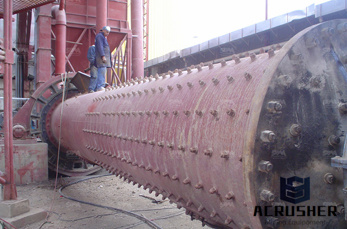

Cement kiln Wikipedia, the free encyclopedia Over a billion tonnes of cement are made per year, and cement kilns are the heart of this production process: their, 1 The manufacture of cement clinker; 2 Early history; 3 The rotary ...

The process for making Portland cement Materials that contain appropriate amounts of calcium compounds, silica, alumina and iron oxide are crushed and screened ... The clinker is very finely ground to produce portland (hydraulic ...

The main raw materials used in the cement manufacturing process are limestone, clay, sand, shale and iron ore. Limestone is usually mined on site while the other minor materials may be mined either on site or in nearby quarries.

Cement Manufacturing 277 Air Emissions A maximum emissions level of 50 milligrams per normal cubic meter (mg/Nm 3), equivalent to a maximum of kg/t of clinker, for particulates in stack gases under fullload conditions is to ...

The clinker manufacturing process The clinker manufacturing process starts with the extraction of the raw meal from the homogenization silo to insure that the raw meal is stable and homogenized in order to produce consistent clinker ...

Cement Clinker Manufacturing Process Manual What is cement? Cement is a fine powder which sets after a few hours when mixed with water, and then hardens in a few days into a solid, strong material. Cement is mainly used to ...

The invention relates to a process for manufacturing cement clinker in a plant comprising a cyclone preheater, a precalcination reactor, a rotary furnace and a clinker cooler, in which process the flue gases from the furnace are ...

WhatsApp)

WhatsApp)