WhatsApp)

WhatsApp)

With given options choice of refractories is extremely important for smooth running of the kiln Obvious choice has been basic bricks Made in India Basic Refractory Bricks for Cement Kilns Cement manufacturing has under gone a sea change in the recent past The wet process which had been the main technique until 1960 has been replaced by dry process

Thus except for the burning zone the operating condition of cement kiln ''apparently'' is of moderate severity at least from the chemical attack point of view The temperature in the nonburning zone part of the kiln system is not high enough for reaction between

Aug 11 2015· ACC Ltd among India''s foremost cement manufacturers has been conferred the prestigious Golden Peacock Award for EcoInnovation this year over their efforts to provide coprocessing of waste management in cement plants The Group of Ministers on the Bhopal Gas tragedy have abandoned the plan to burn down 350 tonnes

Indian Cement Industry is the second largest cement producer in the world after China with a total capacity of 1512 Million Tonnes MT The Indian cement industry is dominated by 20 companies which account for almost 70 of the total cement production in India

Cement kiln coprocessing has been amply demonstrated for its safe disposal capability for wastes through many trials in India Coprocessing is now being implemented successfully of different kinds of wastes including hazardous ones in 55 cement plants across the country and is gaining momentum

List of Top Cement Companies in India The top cement companies in India in terms of market capitalisation are as followsUltraTech Cement The biggest player in the Indian cement industry is UltraTech Cement a product of the Indian multinational conglomerate – the Aditya Birla Group that was founded in 1857

Ramco Cement is the company which was founded in 1894 and has been successfully able to steal the fifth spot on our list of the top 10 cement companies in India This company has a production capacity of 1645 million tons per year and has successfully carried itself this far

As of December 2018 Raysut Cement Company is planning to invest US 700 million in India by 2022 During 201718 Ultratech commissioned a greenfield clinker plant with a capacity of 25 MTPA and a cement grinding facility with 175 MTPA capacity in Dhar Madhya Pradesh

The production of cement in India grew at a very faster rate During the year 1994 to 1995 the production of cement was 5835 MT It was more than double in the year 200304 with 1175 MT Further there was a sharp rise in the production of cement to 17897 MT in the year 201112

Cement Industry in India is growing at the rate of 8 per annum owing to numerous plants of cement spread across the country from North to South and East to West

Sep 29 2019· Explore cement kiln profile at Times of India for photos videos and latest news of cement kiln Also find news photos and videos on cement kiln Fri Nov 15 2019

RDF from MSW to be used as partial fuel in cement kiln This may be included as a part of CSR programme to manage the MSW disposal problem Fly ash ESP ash should be used to produce fly ash pozzolona cement Thermal power plant cement plants should setup cement grinding unit

Indias cement production is expected to rise between 57 per cent in FY20 backed by demands in roads urban infrastructure and commercial real estate Cement production is expected to grow to 316 million tonnes in 201819 It reached 30420 million tonnes between April 2018 February 2019

Cement Plant Location Information for India Cement plant locations and information on India can be found below For full access to the database purchase The Global Cement Report 13th Edition

Used for diverse commercial and industrial applications our Cement Kiln is offered with turnkey sponge iron plants We are the foremost Manufacturer and Supplier of Cement Kiln in India thus take great care while designing it Our Cement Kiln can be acquired at the market leading prices

The rotary kiln has an important role to play in the cement manufacturing process taking place in the cement plant At Technomart we specialize in manufacturing efficient and performanceoriented rotary cement kilns for successful completion of cement production

Dalmia Cement Set up by noted industrialist Jaidayal Dalmia Dalmia Cement is India''s 4th largest cement company by installed capacity It offers customers a wide variety of cement products under the Dalmia Cement Konark Cement and Dalmia DSP brands

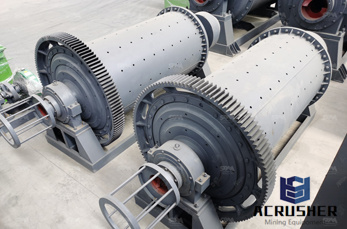

Kiln and Kiln Shells As a Cement kiln manufacturers we manufacture all type of process equipments including Vertical and roller Kiln and Shells Kiln Shells is involved in the process of burning the raw mixture thereby resulting in the clinker This clinker is then subjected to grinding to produce cement

Apr 16 2016· The cement company is an extension of Aditya Birla group and manufactures grey cement readymix concrete white cement Portland cement Portland blast furnace slag cement and Pozzolana cement The brand as 18 integrated manufacturing plants 25 grinding units seven bulk terminals and one cinkerisation plant across India

Cement White Cement Portland Blast Furnace Slag Cement and Specialised Cement The basic difference lies in the percentage of clinker used Ordinary Portland Cement OPC OPC popularly known as grey cement has 95 per cent clinker and 5 per cent gypsum and other materials It accounts for 70 per cent of the total consumption

The cement kiln is a typical example of a sintering furnace Kilns are used in the cement industry for calcining lime and are made in various forms Rotary cement kilns as used in the cement industry take the form of a long cylinder supported on rollers They vary greatly in diameter and length from 15 ×

WhatsApp)

WhatsApp)