WhatsApp)

WhatsApp)

A boiler or Steam Generator prime mover is an integral device in a fossil fuel power plant used to produce steam by applying heat energy to water A boiler incorporates a furnace in order to burn the fossil fuel coal gas waste etc and generate heat which is transferred to water to make steam

A coal based thermal power plant converts the chemical energy of the coal into electrical energy This is achieved by raising the steam in the boilers expanding it through the turbine and coupling the turbines to the generators which converts mechanical energy into electrical energy

Optimized coal pulverizer performance is a prerequisite for ensuring the best furnace combustion efficacy Here are some solutions for overcoming commonly identified combustion problems Coal

RingRoll BowlMill and BallRace Mills comprise the majority of coal pulverizers currently in service at power generating facilities In this design the grinding rolls are stationary while the ring or bowl as it is sometimes called is rotated by a worm gear drive

Coal In a coal based thermal power plant coal is transported from coal mines to the generating station Generally bituminous coal or brown coal is used as fuel The coal is stored in either dead storage or in live storage Dead storage is generally 40 days backup coal storage which is used when coal supply is

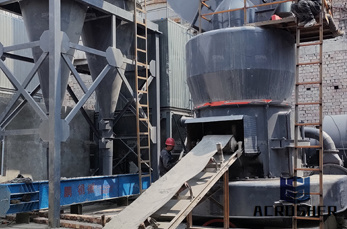

Oct 26 2016· For example a pulverizer mill is used to pulverize coal for combustion in the steamgenerating furnaces of fossil fuel power plants Pulverizing the coal to a fine powder is an important function in the operation of a power plant This article explains the different methods of pulverizing The key input to the coal fired power plant is the coal

Coal mill pulverizer in thermal power plants SlideShare pulverizermill system One of the critical power plant components that is relied upon to convert the energy stored in coal into electricity is the coal pulverizer or mill types of coal mills in a thermal power plant

Nov 09 2012· pulverizermill system One of the critical power plant components that is relied upon to convert the energy stored in coal into electricity is the coal pulverizer or mill The coal flow is controlled by the feeder allowing coal to flow into the pulverizer mill The pulverized coal and air mixture is then transport to the boiler burner panels

To help ensure your coal milling assets are performing per your plant''s key performance indicators we offer a full line of parts service and solutions Read below for stats surrounding coal pulverizer performance improvements as a result of GE Steam Powers coal and boiler service solutions

Coal In a coal based thermal power plant coal is transported from coal mines to the generating station Generally bituminous coal or brown coal is used as fuel The coal is stored in either dead storage or in live storage Dead storage is generally 40 days backup coal storage which is used when coal supply is unavailable

Nov 17 2012· pulverizermill system One of the critical power plant components that is relied upon to convert the energy stored in coal into electricity is the coal pulverizer or mill The coal flow is controlled by the feeder allowing coal to flow into the pulverizer mill The pulverized coal and air mixture is then transport to the boiler burner panels

Boilers machinery Coal Pulverizer Thermal Power Plant ENERGY Pulverizers coal pulverizer are used to pulverize pieces of coal into fine particles 100μm before placing into a boiler to ensure efficient combustion For more information MITSUBISHI HITACHI

coal millpulverizer in thermal power plants shivaji choudhury uction uction Coal continues to play a predominant role in the production of electricity in the world A very large percentage of the total coal is burned in pulverized form

Coal Mill Pulverizer In Thermal Power Plants Pulverizermill system one of the critical power plant components that is relied upon to convert the energy stored in coal into electricity is the coal pulverizer or mill the coal flow is controlled by the feeder allowing coal to flow into the pulverizer mill read mode

Nov 17 2012· COAL MILLPULVERIZER IN THERMAL POWER PLANTS SHIVAJI CHOUDHURY allowing coal to flow into the pulverizer mill The pulverized coal and air mixture is then transport to the boiler burner panels Medium High 10 to 20 40 to 70 900 to rpm rpm 1000 rpmType Ball tube Bowl Hammer mill Ball race mill millDominating Attrition Crushing

Power generation industry studies have shown that coal pulverizers are an area where improved equipment reliability is badly needed The Electric Research Institute EPRI has determined that 1 of plant availability is lost on average due to pulverizerrelated problems1 EPRI also identified oil contamination and excessive leakage as two

coal pulverizer pictures in power plants dubaiPulverized coalfired boiler Wikipedia the free encyclopedia A pulverized coalfired boiler is an industrial or utility boiler that generates thermal energy by burning pulverized coal alsoThis plant became the first central power station in the United States to use pulverized powdered coal from the pulverizer is directly blown to a burner in the boiler

Mar 28 2017· In a thermal power plant the raw coal transported via trucks or railways is first crushed to smaller size in a crusher This coal is then fed to a coal mill where it is crushed to a fine particle form by applying force either by hammering or by combined effect of compressive and shearing forces

In a coal based thermal power plant the initial process in the power generation is "Coal Handling" So in this article i will discuss the overall processes carried out at a Coal Handling plant in a coal based thermal power generating station The huge amount of coal is usually supplied through railways

Sep 12 2019· Produces 15 times the amount of product when processing ores This costs 100mB of Tectonic Petrotheum per operation and the Pulverizer consumes 50 more power per operation This augment also gives the Pulverizer a 4bucket internal tank that can be input into from any side

WhatsApp)

WhatsApp)