WhatsApp)

WhatsApp)

Wm = Wi (P80 10 F80 10) (1) where: Wm is mill specific motor output power (kWh/t), Wi is the Bond ball mill work index (kWh/t), P80 is sieve size passing 80% ...

A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust. Crushers may be used to reduce the size, or change the form, of waste ...

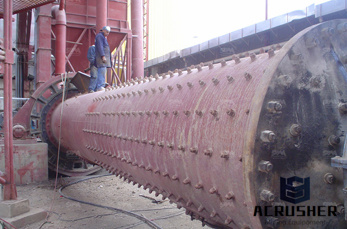

Ball milling. A device used to reduce the particle size of materials, bodies or glazes. A ball mill is simply a container that is filled with pebbles (either of porcelain or stones Flint) into which a charge (powder or slurry) is put and that is then mechanically rotated to cause the tumbling pebbles to crush particles that happen between them.

Milling and Size Reduction of High Purity Materials using Ball Milling Technology ... milling to reduce particle size is a ... milling, size reduction Process: Ball ...

A ball mill can grind and homogenize small sample volumes down to the ... Particle Analyzer; Sieve ... A ball mill for powerful size reduction and homogenization.

Propellant Preparation Methods. Grinding. Grinding is done to reduce the chemicals to a very small particle size. This is required for any compressed powder motors ...

Complete package that includes: a) machine simulation teaches the student the setup and operation of CNC machines. b) CNC program simulation and gcode debugger ...

The ability of a mineral to float depends upon its surface properties. Chemical modification of these properties enables the mineral particles to attach to an air ...

Intro: Make a Ball Mill in 5 Minutes. This is for all the pyro nuts that I came across on Instructables. This can be used to grind chemicals to a very fine grain or ...

The energy emitted from lasers is highly concentrated and can cause permanent eye injury. Although engineering controls are preferred to reduce ...

Biography: Published textbook Mecánica Cuántica (now in its 3rd edition, 2015); first and second editions sold over 2,000 copies. Also, published over 230 research ...

Type of Mill Media Size, in. Tip Speed, ft./sec. Ball mill ½ and larger ... on larger media to reduce particle size to a level that can be handled in

kilns, are used for firing tile. Wall tile, or tile that is prepared by dry grinding instead of wet milling (see #2 and #3 above), usually requires a two ...

Shop for brand new laboratory mills and grinders at Norstone. We carry lab grinders and mills for many different applications and budgets.

Raw Materials Dictionary / Ceramic Pottery Glaze making, Clay Ingredients

Laboratory Ball mills and ring mills and other types of mills are used for fine level comminution or particle size reduction. ... Planetary Ball Mill from Retsch.

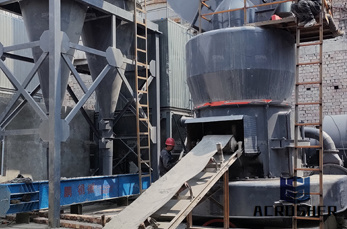

Cement grinding Vertical roller mills versus ball mills Soeren Worre Joergensen MSc, General Manager, Engineering, Grinding Technology

Pharmaceutical particle technologies: An approach to improve drug solubility, dissolution and bioavailability

New York importer, distributor and fabricator of natural stone products and ceramic tiles.

How to safely and effectively use a ball mill to ... ball milling is the best way for the amateur fireworker to reduce particle size in ... Ball milling replaces ...

ADVANCED SCIENCE LETTERSis a multidisciplinary peerreviewed journal with a very wideranging coverage, consolidates fundamental and applied ...

The history of technology, history of science, history of inventions, the scientific revolution, the industrial revolution, the internet, space, communications ...

Mineral processing is a major division in the science of Extractive Metallurgy. Extractive metallurgy has been defined as the science and art of extracting metals ...

... the smaller the particle size of the ... Ball milling boasts ... mill called a planetary ball mill. Planetary ball mills are smaller than common ball ...

WhatsApp)

WhatsApp)