WhatsApp)

WhatsApp)

Aug 30 2012· Kiln is a huge rotating furnace also called as the heart of cement making process Here raw material is heated up to 1450 ⁰C This temperature begins a chemical reaction so called decarbonation In this reaction material like limestone releases the carbon dioxide

chemical and physical requirement of cement Cement is defined as the product manufactured by burning and crushing to powder an intimate and wellproportioned mixture of calcareous and argillaceous materials

In 1990 seven cement plants reported to the Portland Cement Association PCA that their primary fuel included waste three reported using a combination of coal and waste as primary fuel2 The type of waste was not specified and therefore the number burning tires or TDF specifically could not be determined

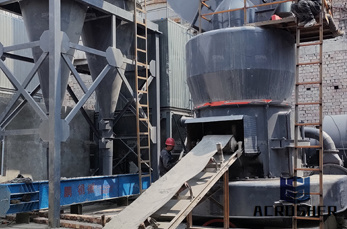

Aug 27 2015· Cement Manufacturing Process Mixing of raw materials The raw materials such as limestone or chalk and shale or clay may be mixed Burning In modern technology of dry process the coal brought from the coal fields is pulverized in Grinding The clinkers as

Cement manufacturing is a complex process that begins with mining and then grinding raw materials that include limestone and clay to a fine powder called raw meal which is then heated to a sintering temperature as high as 1450 °C in a cement kiln In this process the chemical bonds of the raw materials are broken down and then they are recombined into new compounds

Manufacture Process of Cement The manufacture procedures of Portland cement is described below Mixing of raw material Burning Grinding Storage and packaging 1 Mixing of raw material The major raw materials used in the manufacture of cement are Calcium Silicon Iron and Aluminum

Manufacture of cement Crushing and grinding All except soft materials are first crushed often in two stages Blending A first approximation of the chemical composition required for a particular cement is Burning The earliest kilns in which cement was burned in batches were bottle

Aug 30 2012· Cement Manufacturing Process Phase 1 Raw Material Extraction Cement uses raw materials that cover calcium silicon iron and aluminum Such raw materials are limestone clay and sand Limestone is for calcium It is combined with much smaller proportions of sand and clay Sand clay fulfill the need of silicon iron and aluminum

Cement in general adhesive substances of all kinds but in a narrower sense the binding materials used in building and civil engineering construction Cements of this kind are finely ground powders that when mixed with water set to a hard mass

Oct 24 2007· The anatomical distribution of cement burns to the lower leg foot and ankles Fig Fig11 and to the knees is consistent with other studies 4 Floorers had burns on their knees from having to kneel while spreading cement and the added effect of pressure increasing the severity of the burns

Energy costs and environmental standards have encouraged cement manufacturers worldwide to evaluate to what extent conventional fuels can be replaced by different alternative fuelsie processed waste materials The clinker burning process is well suited for the use of various

Raw Materials processing included Setting and curing and cement manufacturing process Process Discretion Wet process Semidry process Dry process and Finish process The environmental impact of the cement production and its variations between different

Wet process kilns The original rotary cement kilns were called wet process kilns In their basic form they were relatively simple compared with modern developments The raw meal was supplied at ambient temperature in the form of a slurry A wet process kiln may be up to 200m long and 6m in diameter

The heated air from the coolers is returned to the kilns a process that saves fuel and increases burning efficiency After the clinker is cooled cement plants grind it and mix it with small amounts of gypsum and limestone Cement is so fine that 1 pound of cement contains 150 billion grains

At least three chemical changes are known to take place in the brickearth during the burning process dehydration oxidation and vitrification Dehydration It is completed within the temperature range of 425 – 750° C Bricks heated to this temperature lose all the

The heart of the portland cement manufacturing process is the pyroprocessing system This system transforms the raw mix into clinkers which are gray glasshard spherically shaped nodules that range from 032 to 51 centimeters cm 0125 to 20 inches in in diameter The chemical

Dec 11 2018· burning zone toward kiln outlet and then make coating in this section if you have another ideaplease help us quickly A 370 to 390 degrees C is high but not dramatically so It is not uncommon to have shell temperatures this high in the burning zone of a cement kiln lined with magnesia spinel refractories • Back to Top Q kiln shell temperature

During the burning process the components that can evaporate are evaporated and the only component left are the silicates The rice husk ash to be more precise have characteristics based on the components the temperature of burning and the time of burning

Jun 10 2014· Cement manufacturing process 1 is cement y iw of Cement Manufacturing process iw of Kiln process burn wastes 2 Portland Cement A hydraulic cement made by finely powderising the clinker produced by calcining to incipient fusion a mixture of argillaceous and calcareous materials

WhatsApp)

WhatsApp)