WhatsApp)

WhatsApp)

Lump ore produced from the processing plant will range in size from 8mm to 40mm while Fines ore will be less than 8mm in size This top deck of the screen separates oversize material 40mm which is then tertiary crushed for further size reduction The lower deck separates material into

The iron ore process route For this theoretical scenario a mediumgrade hematite deposit with an average quality of approximately 58 per cent Fe has been

Lump ore produced from the processing plant will range in size from 8mm to 40mm while Fines ore will be less than 8mm in size This top deck of the screen separates oversize material 40mm which is then tertiary crushed for further size reduction The lower deck separates material into Lump product 8mm to 40mm

–Process 600th lumpy iron ore • DMS Cyclone –Only 6mm material for iron ore –360mm diameter cyclone –Process 40th per cyclone • Larcodems –906mm stones –12m diameter –Operating capacity of 600800th –Efficient separation at SG''s as high as 41gcm3 Dense Media Separation on Iron Ore •

Iron ore is found in nature in the form of rocks mixed with other elements By means of various industrial processes incorporating cuttingedge technology iron ore is processed and then sold to steel companies The iron ore produced by Vale can be found in houses cars and household appliances

Iron processing use of a smelting process to turn the ore into a form from which products can be fashioned Included in this article also is a discussion of the mining of iron and of its preparation for smelting Iron Fe is a relatively dense metal with a silvery

Iron ore is found in nature in the form of rocks mixed with other elements By means of various industrial processes incorporating cuttingedge technology iron ore is processed and then sold to steel companies The iron ore produced by Vale can be found in houses cars and household appliances

Iron Ore Efficiently remove silica and alumina contamination to increase efficiencies in steel production Our iron ore processing plants are proven to successfully deal with silica and alumina contamination in the iron ore resulting in an increase in the Fe value of the iron ore thereby increasing the efficiency of the steel production process

Mar 14 2014· The process of mining consists of discovery of an iron ore deposit through extraction of iron ore and finally to returning the land to its natural state It consists of several distinct steps The first is discovery of the iron ore deposit which is carried out through prospecting or exploration to find and then define the extent location and

Aug 07 2019· In 1956 the giant Northshore Mining plant on the shores of Lake Superior was the first facility built in North America to make pellets out of taconite a lowgrade iron ore It used a process developed at the University of Minnesota after the supply of highgrade natural ore in the state was nearly mined out Now more

In the light of various expansion plans of manufacturing as raw and captive source of iron ore for the sponge iron plant the Company has applied for mining lease at Surjagarh Iron Ore Mine Wooria Hills Presently Lloyds are doing iron ore mining operation in Gadchiroli by open cast method at

Process Flowsheets High grade concentrates and high recovery of iron ore can be achieved using effective feed preparation systems typically controlled crushing screening milling classification and slimes removal in combination with cost effective efficient metallurgical separation

The project aims to build a resilient and longlife iron ore mine in Sierra Leone and to expand its operations by integrating mining processing and rail and port logistics The processing plant which has now been operational since 2017 and divided into Phase 1 2 aims to spend approximately US 300 million during its two phases

Based on the iron ore processing experience and necessary processing tests Prominer can supply complete processing plant combined with various processing technologies such as gravity separation magnetic separation flotation etc to improve the grade of TFe of the concentrate and get the best yield

Mar 14 2014· The process of mining consists of discovery of an iron ore deposit through extraction of iron ore and finally to returning the land to its natural state It consists of several distinct steps The first is discovery of the iron ore deposit which is carried out through prospecting or exploration to find and then define the extent location and value of the ore body

Jan 20 2017· Mining iron ore begins at ground level Taconite is identified by diamond drilling core samples on a grid hundreds of feet into the earth Taconite rock comprises about 28 percent iron the rest is sand or silica These samples are analyzed and ca

At the processing plant the taconite is crushed into very small pieces by rock crushing machines The crushers keep crushing the rock until it is the size of a marble The rock is mixed with water and ground in rotating mills until it is as fine as powder 4 Separation The iron ore is

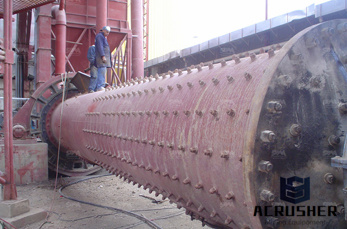

Production Process of Iron Ore Generally the processing of iron ore needs several processing stages including crushing grinding ore beneficiation concentrating drying etc The equipments for iron ore beneficiation is consisted of Jaw Crusher Ball Mill, Classifier Magnetic Separator Flotation Machine Concentrator Machine and Dryer And Equipped with Feeder Elevator and Conveyor a full set of Beneficiation Production

Iron ore mining Itabiritic ore is excavated by bulldozers loaded by frontend loaders into 177tcapacity trucks and taken to a crushing and screening plant in the blending yard The ore is blended and stored before transport by belt conveyors to the surge pile

The following describes operations at the National Steel Pellet Company an iron ore mining and processing facility located on the Mesabi Iron Range of Minnesota Creating steel from lowgrade iron ore requires a long process of mining crushing separating

This is where the processing plant of Scandinavia''s biggest iron ore producer is located with a facility for direct loading of iron ore pellets onto ships The existing plant has a processing rate of 6000 th and a new plant with a processing rate of an additional 9000 th had to be added

Presently Lloyds are doing iron ore mining operation in Gadchiroli by open cast method at Surjagarh Wooria Hills for captive generation of iron ore Hematite Location of the mine The mine is located near Bande village in Etapalli tehsil of Gadchiroli district in the state of Maharashtra

WhatsApp)

WhatsApp)