WhatsApp)

WhatsApp)

Mining Flotation Flotation is an incredibly robust and versatile process that is well accepted around the world It works equally well on mixed sulfide oxide silicate and other ores It relies on generating a population of bubbles of suitable size that can carry the hydrophobic target mineral usually but not exclusively sulfide minerals

Flotation machine 1 Slurry tank mainly consist of a slurry inlet slurry tank and a gate device for controlling 2 Agitator slurry tank have a series of the mechanically driven impeller that disperses the air into 3 Mineralized forth discharging the useful minerals are enriched in the

Mining Equipment Manufacturer Mining Machine Supplier JXSC Mining works on offering services for the mines and mineral processing plants escorting efficient and safe processing performance in the global mineral resources industry with our reliable mining equipment and innovative solutions

About 66 of these are mineral separator 1 are mixing equipment and 1 are other food processing machinery A wide variety of flotation process equipment options are available to you such as gravity separator flotation separator and sprial separator There are 1880 flotation process equipment suppliers mainly located in Asia

Flotation process can maximum enrich gold to the sulfide mineral tailings can be abandoned directly the cost of processing plant is low 80 of Chinas rock gold are used in this method Flotation process that mainly including dosing mixing filling blowing foam etc

Mining Flotation Equipment SGS is the industry leader in flotation testing design and technology With the expertise gained over 70 years our professional staff has developed equipment and monitoring technologies that can help to optimize your circuit and improve your recovery

Additional conditioners are normally required between flotation operations which produce individual mineral concentrates Each conditioner stage should consist of a

JXSC Mining Equipment for sale Complete mineral processing equipment rock crusher gold wash plant magnetic separator magnetic separators flotation machine etc

JXSC provides flotation equipment since 1985 widely used in the gold flotation processing gold washing plant combine with gold trommel spiral chute trommel scrubber gold mining equipment

flotation8 furnaces and ovens25 pumps12 scales10 screens17 separators7 misc lab equipment13 autoclaves 9 autoclaves5 pressure vessels3 c i p systems1 boilers 6 boilers6 blowers 29 centrifugal blowers27 lobe type blowers1 parts and components1 breakers 2 rock breakers2 coal breakers0 buildings 3 buildings3 cement equipment 8

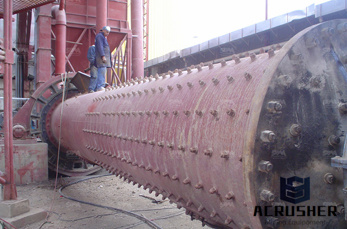

Fluorite flotation equipment is the similar with other mineral flotation equipment including crusher ball mill flotation machine etc Kaolin Mining Process Dry And wet separation are the two main Kaolin mining process of Xinhai

Metallurgical ContentPlanning the lab flotation testFlotation ReagentsFlotation Equipment PreparationSample OriginBatch Laboratory Test PlantContinuous Laboratory Test Plant Batch Laboratory Flotation Testing starts from the 3 fundamental types of flotation processes or methods which can be classed as either Bulk flotation Differential flotation Sequential flotation While all flotation

Process description In the flotation process of the major steps that must be done include the process destruction of rock minerals milling flotation drying and smelting 1 Crushing and Grinding stage 2 Classifying stage are the same as Gravity process 3 Mixing and Flotation stage The classified ore gets into mixing tank for fully mixing

Flotation machine in the ore dressing mainly used for separating copper zinc lead nickel gold and other nonferrous metal can also be used for ferrous nonmetallic crude and selected

That''s all 7 main variables affecting froth flotation Contact us to know more info about industrial gold mining equipment get free froth flotation PDF flotation process flow chart and related industry cases of gold froth flotation zinc froth flotation copper flotation ore flotation

Mining Flotation Equipment SGS is the industry leader in flotation testing design and technology With the expertise gained over 70 years our professional staff has developed equipment and monitoring technologies that can help to optimize your circuit and improve your recovery

You are here Mining Surplus » Equipment » Mill Process Flotation Mill Process Flotation 1 items were found in Mill Process Flotation OTHER GEARBOXES EURODRIVE CW INPRO BRG ISOLATOR SEALS Price Negotiable

For flotation mining equipment APT offers the Trifloat system The TriFloat can be used on sulphide oxide or silicate minerals particularly suited to highyield flotation circuits such as graphite recovery

The Eriez Flotation Division EFD provides advanced engineering metallurgical testing and innovative flotation technology for the mining and minerals processing industries Strengths in process engineering equipment design and fabrication position EFD as a leader in minerals flotation systems around the world

NEW AND USED FLOTATION FOR SALE In gold mining froth flotation is used to separate gold from gangue by utilizing gold''s hydrophobicity Flotation uses bubbles that are introduced into a pulp and rise through the pulp In the process hydrophobic particles gold and other minerals become bound to the surface of the bubbles

Aug 03 2019· Lime is a lowcost item that is widely used in gold beneficiation plants The following is a systematic description of lime properties its role in flotation cyanidation amalgamation and other mining operations for your reference

The gold CIL process is mainly used in the oxide ore which has low grade of silver its more economize and has more benefit Process introduction CIL process is mainly include decontaminate concentrate before leaching leaching and adsorption desorption and electrowinning hydrometallurgy regeneration of activated carbon, tailings filting waste water treatement and so on

At a mining operation a project was designed and implemented to develop a process for controlling lead recovery in the flotation plant The metallurgical program consisted of two parts A survey of the current plant process streams was conducted first to assess the performance characteristics of the existing flowsheet and equipment

Oxygen has an effect on the flotation process of goldsilver sulfide ore oxidized to different degrees For example when a factory floatation contains gold and silver sulfide ore the use of a large amount of organic matter and anoxic lake water the flotation effect is not good after mixing and aeration the stable mineralization foam is obtained the recovery rate of gold is increased by 10

WhatsApp)

WhatsApp)