WhatsApp)

WhatsApp)

Re Shaft kilns The cheapest option to set up a cement factory in Africa would probably to use shaft kiln technology However it depends what you mean by cheap With a shaft kiln you will save on the kiln technology compared with a rotary kiln but you will still have all

VSK Vertical shaft Kiln Cement Plant Ashoka Group offering Vertical shaft kiln cement plants high efficiency cost effective energysaving Cement plants based on VSK technology designed and developed by our efficient and dedicated team of various individuals

Finally the clinker is taken out of kiln bottom Cement Mill and Finishing Thus the clinker formed in Vertical Shaft Kiln will be fed into the cement mill hopper by means bucket elevator where 2 Gypsum will be added and fed to the ball mill for grinding operation Gypsum helps in initial setting of cement

The kiln in cement plant can be divided into cement rotary kiln and vertical shaft kiln They are both the commonly used cement kiln in the cement production line AGICO offers quality cement equipment like cement kiln cement crusher etc

Jul 02 2008· CLINKER FROM ROTARY OR VERTICAL SHAFT KILN Dear Sirs what is the difference between a clinker produced in a rotary kiln and the clinker produced in a vertical shaft kiln I know that the disadvantages of the VSK kiln are the inclusion of ash in the clinker the problem with homogeneity of heat distribution the low production

cement manufacturing using vertical shaft kiln technology vertical shaft kiln technology in cement vertical shaft kiln technology for cement china Heavy Industry is a leading manufacturing and selling of vertical shaft

VSK Cement Plants Chanderpur Works Pvt Ltd is offering Vertical Shaft Kiln Cement Plant from 50 TPD to 300 TPD on turnkey basis Vertical shaft kiln technology is approved by National Council of building material Govt of India and Cement Shaft Kiln is modern day answer for cost effective production and a boon for the developing countries

Rotary Kiln Cement Plant Manufacturing Process Crushing Proportioning In cement manufacturing process the main raw material is limestone grinding which is crushed and transported to the preblending stockpile by means of a belt conveyor

Description of the technology process in shaft kiln The calcination of dolomite stone which is one of the main stages of the sintered dolomite manufacturing is chemical process which proceeds in a vertical shaft or rotary kiln

JN series Cement Concrete Mixer is planetary Cement Concrete Mixer Cement Concrete Mixer productswhich has vertical mixing shaft concrete mixer Get Price cement manufacturing using vertical shaft kiln technology

Dec 17 2016· The kiln of the pyro processing plant is the heart of the cement plant Cement manufacturing processes termed according to the condition of the feed entering the kiln are Wet Dry Semi wet and Semi dry

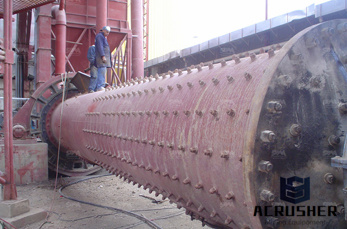

Wet Process The rotary kiln is an essential and important component of a cement manufacturing factory It is made of a thick steel cylinder of diameter anything from 3 meters to 8 meters lined with refractory materials mounted on roller bearings and capable of rotating about its axis at

Protechglobal Consulting Services offers Vertical Shaft Kiln VSBK cement plants from 100 TPD to 600 TPD on turnkey basis Vertical shaft brick kiln technology is adopted by customers for projects of smaller capacity for its low cost implementation

mini cement plants based on Vertical Shaft Kiln technology suiting the small from ECON 101 at Harrison College

Cement is so fine that 1 pound of cement contains 150 billion grains The cement is now ready for transport to readymix concrete companies to be used in a variety of construction projects Although the dry process is the most modern and popular way to manufacture cement some kilns in the United States use a wet process

Manufacturing the cement kiln Most Portland cement is made in a rotary kiln Basically this is a long cylinder rotating about its axis once every minute or two The axis is inclined at a slight angle the end with the burner being lower

under gravity Parallel evolution of shaft kiln technology with the more complex dry process rotary kilns kept the mix of pyroprocessing technologies in Chinas cement industry more diverse than in almost any other country Coal is the primary fuel burned in cement kilns but petroleum coke natural gas and oil are also consumed

Cement shaft kiln is used for calcination in cement plante offer 50 tpd to 300 tpd vertical shaft kiln on turnkey basis for cement plant cement shaft kiln is modern day answer for cost effective production and a boon for the developing countriessk is the advanced technology

New chapters include finish grinding using vertical roller mills oxygen enrichment inlet gas analysis and acoustic pyrometry Sustainability and the environment are covered frequently with new chapters on sustainable cement manufacturing and carbon capture and carbon sequestration along with carbon dioxide reduction and control

AGICO Cement is a cement equipment manufacturer from China supplies various cement kilns with rich experience and high quality We are specialized in shaft vertical kiln cement rotary kiln and related cement equipment in the clinker plant

When a vertical shaft kiln is used to produce portland cement clinker it is essential that the mixture be shaped into nodules lumps bricks or some other extruded shape in order to allow ready passage of hot gases through the mixture bed to accomplish heating to the clinkering temperature

manufacturing process of cement in vertical shaft kiln Manufacturing process of cement in Traduire cette pageSmallScale Production of Portland Cement Cement Cement manufacture by using a modern verticalshaft kil

Aug 30 2012· Kiln is heating up from the exit side by the use of natural gas and coal When material reaches the lower part of the kiln it forms the shape of clinker Cement Manufacturing Process Phase V Cooling and Final Grinding After passing out from the kiln clinkers are cooled by mean of forced air

WhatsApp)

WhatsApp)