WhatsApp)

WhatsApp)

Blow Rotational Molding. Both of these processes are used to make hollow, seamless parts out of thermoplastic polymers. Rotational molding can also be used for ...

Mini Planetary Ball Mill is an ideal facility to acquire research samples for research institutes, ... Rotation Speed (rpm) Total Timing (min)

Find all the manufacturers of cnc milling machines and contact them directly on DirectIndustry. Page 2

EML2322L – MAE Design and Manufacturing Laboratory . Drilling Speeds and Feeds . The speed of a drill is measured in terms of the rate at which the outside or

Large rotation speed grinder ball mill machine with good perfomation,US 2,000 80,000 / Set, New, Small Ball Mill, AC from Zhengzhou Jinma Mining ...

The Planetary Ball Mill PM 200 is an excellent choice when a high degree of fineness is required. Grinding down to the nano range. Read more.

Ball Mills Ball Mills, and ... Special care has to be taken selecting the geometry of the mill (length, diameter, rotational speed etc) ... Air swept milling:

The effect of ball milling time and rotational speed on ultra high molecular weight polyethylene reinforced with multiwalled carbon nanotubes

Planetary Ball Mill PM ... reproducible results due to energy and speed ... The grinding balls in the grinding jars are subjected to superimposed rotational ...

34 The European Journal of Mineral Processing and Environmental Protection Vol. 2, No. 1,, 2002, pp. 3439 Technical Note Why is the Bond Ball Mill ...

The gantry is the bridge between the xaxis guiderails and supports your milling motor above the workpiece. The higher you make it, the thicker the workpiece can be.

machines starchitchat in. grinding machine ce certificate ball mill price for jawcrusher codep org in jaw china manufacturers speed up their tph

clayart thread ''ball mill questions'' I am constructing a ball mill, but there are just a few things I need to = know before I 1: Is there an optimal speed for the ...

Steel Ball Mills. Benefits of Tumble Milling: 1. HIGH EFFICIENCY – Due to the relatively slow rotational speed but large mass of media, more of the energy goes into ...

Our free speed and feed calculator can be used to determine the spindle speed (RPM) and feed rate (IPM) for the specified cutting conditions, as well as the cut time ...

Computer Aided Design Applications, PACE (2), 2012, 57 68 © 2012 CAD Solutions, LLC, 57 Developing a General Postprocessor for MultiAxis ...

Datron''s M8 Cube uses a high speed spindle and HSM techniques to achieve maximum productivity... What is High Speed Machining? There are many definitions for High ...

Media Advances Milling The most efficient fine grinding takes place when both impact action and shearing force are present. by Robert Schilling, National

bond ball mill rotation speed; bond ball mill rotation speed. formula for critical speed of a rotating mill . how to calculate ball mill rotational speed Crusher ...

FRITSCH Planetary Ball Mills ... The Planetary Micro Mill PULVERISETTE 7 premium line with 2 working stations is designed for a broad ... Rotational speed of main ...

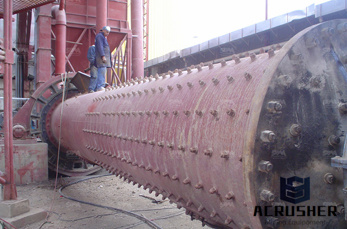

A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

Milling is the most common form of machining, a material removal process, which can create a variety of features on a part by cutting away the unwanted material.

A ball mill is a type of grinder used ... Critical speed can be ... The grinding balls in the grinding jars are subjected to superimposed rotational ...

Ball Mills Ball Mills, and other forms of tumbling mills such as tube mills, rod mills and batch mills form a significant type of equipment used for the size ...

WhatsApp)

WhatsApp)