WhatsApp)

WhatsApp)

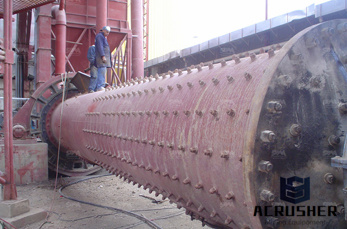

Henan Fote Heavy Machinery Co a professional manufacturer and exporter specilized in the prodution of ball mill magnetic separator rubbletyred mobile crushing station dryer jaw crusher Rotary kiln and other large mining machinery equipment

The loaded carbon is treated by desorption and electrowinning equipment after it could get high grade gold mud The gold mud feed into the smelting equipment to get the final pure gold bars 99 CIL Gold Processing Plant video electric cables control cabinets diesel generator etc

3500 TPD Gold Silver CIL Ore Processing Plant ID 411618 This 3500 TPD CIL plant was put on care and maintenance in 2018 and is now for sale and offered by Savona Equipment Ltd The process plant which has a design capacity of 13 Million TPA comprises of a crushing circuit a ball and SAG mill grinding circuit while precious metal recovery is through a carbon in leach process and electrowinning

Outlining best practices in gold processing from a variety of perspectives Gold Ore Processing Project Development and Operations is a musthave reference for anyone working in the gold industry including metallurgists geologists chemists mining engineers and many others

We manufacture and distribute a unique range of mining and mineral processing equipment for the extraction of gold diamonds tantalite chrome and other minerals These mining products and processes are the result of years of experience and research in the field We usually sell our plants as complete modular mining equipment ''kits''

In most cases gold processing with cyanide leaching usually with carbon adsorption is still the core technology and the critical thing is understanding the mineralogy in order to optimise flowsheet selection and cost drivers and get the best out of the process Metallurgy the science of bashing

Gold Trommel trommel scrubber are the main mining equipment in the gold wash plant used for washing alluvial typesand type ores and stones

available for the extraction of gold metal from its ores Amongst these methods cyanidation is the most common method used in the leaching of gold from the ore This process involves the dissolution of gold containing ores in dilute cyanide solution in the presence of lime and oxygen For refractory ores such as

When gold dissolution is complete the goldbearing solution is separated from the solids With ores of higher gold content greater than 20 grams of gold per tonne of ore cyanidation is accomplished by vat leaching which involves holding a slurry of ore and solvent in large tanks equipped with agitators

Prominer maintains a team of senior gold processing engineers with expertise and global experience These gold professionals are specifically in gold processing through various beneficiation technologies for gold ore of different characteristics such as flotation cyanide leaching gravity separation etc to achieve the processing plant of optimal and costefficient process designs

For fine free gold ores of 50 350 micron a conventional gravity box circuit that incorporates a modern centrifugal concentrator is recommended Higher centrifugal g forces extract the free gold particles

Flotation is a method that is widely used in gold ore processing plant to process the rock goldcommonly used in dealing with highly floatable sulfide minerals containing gold ore

More importantly gold in an ore may occur in two or three forms ie microscopic gold submicroscopic gold and surface gold making gold ore processing extremely challenging The objective of gold geometallurgy is to reduce and minimize the technical risk in

All series plants are designed engineered as completely selfcontained portable gold processing plants with everything required for production mining All mobile plants have their own feed hopper classifier primary gold concentrator power system and

The IGR 100 Modular Gold Processing Plant is a selfcontained fine gold recovery equipment system It uses classification and enhanced gravity to assure you are catching the finest gold and the big nuggets In the standard configuration material flows

Mt Baker Mining and Metals is focused on providing a costeffective and durable ore processing plant that includes a jaw crusher hammer mill size classification equipment and sluiceshaker table This is the most efficient combination of cost productivity longevity and recovery when the job calls for processing bulk samples performing test runs or an initial setup to generate revenue flow

Processing chain The best ore yield comes from a threestage process The first stage is a necessity the second or third may optionally be skipped but will reduce yield Stage 1 Macerator Stage 2 Ore Washing Plant Stage 3 Thermal Centrifuge Stage 1

Manufacturers and suppliers of innovative gold mining equipment for sale Our industiral gold prospecting equipment includes sonic sluice boxes micron gold recovery units classifiers wash plants dredges recreational gold recovery plus used mining equipment for sale

In the past year two very innovative gold ore processing plants have been designed built and commissioned by Gekko Systems Pty Ltd The first plant in Vietnam utilizes conventional crushing and ball milling followed by gravity concentration Inline Pressure Jig IPJ and Falcon concentrator

Ore Processing Plants Gold and Silver Ore Processing and Recovery Plants for Sales Savona Equipment is your source for new used and reconditioned Ore Mineral Processing Plants of many types and capacity for large primary ore processing secondary and tertiary fine material concentrating as well as complete aggregate recycling mining

Unique in the industry is our line of innovative Mobil Placer Ore Processing Plants These plants are particularly versatile and economical for alluvial mining projects Well suited for production and exploration stationary or mobile

For fine free gold ores of 50 350 micron a conventional gravity box circuit that incorporates a modern centrifugal concentrator is recommended Higher centrifugal g forces extract

WhatsApp)

WhatsApp)