WhatsApp)

WhatsApp)

MANUFACTURING PROCESS FOR CEMENT The Clinker Grinding Plant requires the following raw materials: Clinker Gypsum Additives The Clinker is procured from Clinker Grinder Unit from India, China, Indonesia, Gulf and ...

Clinker Hopper 6. Ball Mill 3. Gypsum Hopper 7. Cement Storage Silo 4. Bucket Nelevator 8. Bag Packing Machine ¤ Essential Requirement for set up of Clinker Grinding Unit 1 LAND 2 BUILDING a. Main Factory Shed Include b. ...

Cement Grinding Details 1. Raw mill for cement production process Why raw material Grinding? To make the different ingredients into products of a certain granularity, in order to get required size for clinker calcinations. Smaller size ...

The use of a good Cement clinker grinding aid can be vital in today''s increasing material demands. Along with the obligation to process increasingly larger quantities of ores containing finely disseminated minerals, our limited energy ...

3 These differences between cement grinding and grinding of raw materials made it a serious challenge to obtain a good performance of a vertical roller mill in cement grinding. Today, however, the OK mill has become an excellent ...

BREAKTHROUGH IN CLINKER GRINDING By: Richard P. Bohan, Director of Manufacturing Technology, Portland Cement Association, rbohan, and John P. Kline, Principal, John Kline Consulting, johnpklinegmail ...

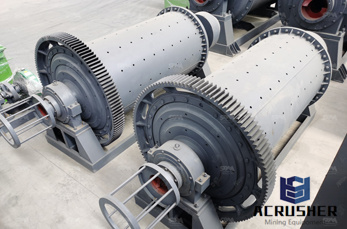

As a professional ball mill manufacturer, Henan Fote Heavy Machinery can produce all kinds of ball mill machines with high quality and reasonable price. Mail to: sales

A cement mill is the equipment that used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement. Most cement is currently ground in ball mills. Cement clinker is usually ground using a cement ...

Cement manufacturing brief description of a cement mill Cement clinker is usually ground using a ball mill. This is essentially a large rotating drum containing grinding media normally steel balls. As the drum rotates, the motion of ...

Grinding Portland cement with a Blaine of 3200 cm 2 /g consumes approximately 23 kWh/t and even for pozzolanic cement with a Blaine of 4000, power use may be as low as 30 kWh/t. Development Status Products Commercial ...

Design and Optimization of Ball Mill for Clinker Grinding in Cement Plant Sanjeev T. Patil Department of Metallurgical and Materials Engineering, Visvesvaraya National Institute of Technology, Nagpur440010, India. Abstract: 1 66 ...

cement clinker grinding mill – SCM Coal Surface Mining cement clinker grinding mill Description : Cement mill – Wikipedia, the free encyclopedia A ball mill is a horizontal cylinder partly filled with steel balls (or >> Get Price cement ...

CNC Machine Job Works in Bala Nag, Hyderabad, Call for CNC Machine Job Works in Bala Nagar, Hyderabad and more ... Punching Machine Dealers · Spinning Mill · Flour Mill Machinery Dealers... Total Status ...

grinding mill is highly effective grinding system which subject the raw material to relatively low heat and pressure levels. It consists of large diameter, rotating cylinders or drums driven by electric motors. The drum is partially ...

Do you want to show cement mill rolling mill for grinding or other products of your own company? Display your Products FREE now!

Clinker Grinding Unit Cement Plant Manufacturer,Cement Bag Packing Machine ¤ Essential Requirement for set up of Clinker Grinding Unit. 1: LAND: 2: BUILDING: a. » Learn More Cement Clinker Grinding mill used in Clinker ...

Price of Cement Mill in Russia,Cement Clinker Grinding Unit In cement plants, proper specifiion and supply is vital to project schedules and delivering efficient plants contains: operating... Get Price Sell Mini ...

green field project cost of 200 tpd clinker grinding unit green field project cost of 200 tpd clinker grinding unit in india. Reduction in cost of concrete Grinding of cement clinker and fly ash together in the Mill. » Learn More Used ...

In this 1,000,000t/y cement grinding plant, clinker and slag are ground separately. PFG12050 rolling machine and Φ×13m cement mill are used in clinker ginding. Φ×13m ginding machine and highefficiency powder ...

Port Kembla grinding mill Cement Australia For most of the twentieth century, the dry grinding circuits for the production of finished cement from cement clinker consist of twocompartment tube mills and the... Cement ...

OPERATIONAL EXPERIENCE FROM THE UNITED STATES'' FIRST VERTICAL ROLLER MILL FOR CEMENT GRINDING By: Mark Simmons Production Manager Salt River Materials Group Phoenix Cement Plant Lee Gorby

In the cement production line, we use cement crusher for cement crushing process, then we need cement mill for fine grinding stage. As a kind of raw material mill, Cement mill is the equipment used for grinding the hard, nodular ...

Cement Grinding Cement Grinding is last process of cement production. Its main function lies in Grinding cement clinker (and gelling agent, performance adjusting Grinding materials) into suitable particle (by fineness and specific ...

CHAENG | Great Wall Machinery provides you:Slag Grinding Plant,Cement Equipment,Vertical Mill,Ball Mill,Rotary Kiln For Quarry, .

WhatsApp)

WhatsApp)