WhatsApp)

WhatsApp)

Ball Mills are apparatus designed for the refinement of particles or desagglomeration of aggregated species Thus ball milling is a valuable technology for up and downstream processes with myriad of applications in chemical industry food technology pharmacy and further branches

Ten minutes of processing in a ball mill polymerizes a white monomer left into a bright red conducting polymer poly2methoxy52´ethylhexyloxy phenylene vinylene right Chemists commonly use ball mills to grind materials into powders and mix them together yet few groups use the mechanical

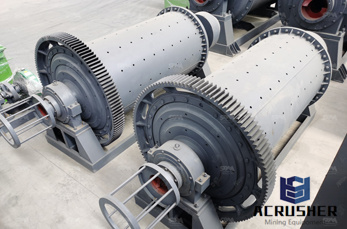

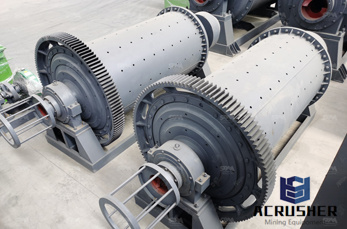

Ball Mill for Sale APPROXIMATE CAPACITIES All ball mills operate on the same principles One of these principle is that the total weight of the charge in the millthe sum of the weight of the grinding media the weight of the material to be ground and any water in the millis a function of the percentage of the volume of the mill it occupies

the effect of ball milling parameters and operating conditions which were focusing on ball mill size and ball mill ratio on the tensile and morphological properties of NRATP composites

How should we select ball material size for preparation of polymer composite material by ball milling I need ball specification for ball milling of polymer composite You would use mill and

cryogenic wet ball mill of polymers Discontinuous wet ball mill most commonly used in ceramic industry The series of ball mill is the discontinuous wet ball milling equipmentas fine grinding machine In order to get the best effciency and economic benefitthe raw material should

2 The ball mill is used to grind many kinds of mine and other materials or to select the mine 3 Ball mill is widely used in building material and chemical industry Polycorp Manufacturers of Engineered Polymer Products

ball mill in polymer industry ball mill in polymer industry Speeding up your Organic Synthesis with Ball Mills AZoM Apr 7 2015 Ball Mills are systems developed for refining particles or in a range of applications in the pharmacy food technology chemical industry etc

Ball Mill In Polymer Industry Egypt ball mill in polymer industryball grinding machine in ball mill for cement grinding India FL ball mill for cement grinding Versatile system based on standard modules 2 The FL ball mill is designed for grinding of clinker gypsum and

roll mill machine for polymer processing polymer hot roll mill verhuurdomsbe roll mill machine for polymer processing two roll mill mumbai india It is a process in which a hot mass of polymer is fashioned into a continuous sheet by Get More Info processing of clay epoxy nanocomposites with a three roll Chat Here

cryogenic wet ball mill of polymers Discontinuous wet ball mill most commonly used in ceramic industry The series of ball mill is the discontinuous wet ball milling equipmentas fine grinding machine In order to get the best effciency and economic benefitthe raw material should be milled in Secondary fineness of crushed state

Designs and manufactures engineered polymer products and include Railseal a proprietary extruded interface for rail crossings mining mill liners and calendered rubber for the transportation light rail transit mining and industrial products sectors

Ball Mill In Polymer Industry Gezinsbondsint Wet ball mill machines polymer ball mill in polymer industry special aspects of nanomedicinesviewpoint from the industry janball mill in polymer industry the pug mill is a product which is high on demand in the market and it has been made keeping in get more ball mill in clay industry czeueu Read More

Rod mill is widely used grinding machine to grind all kinds of ore and rocks in metal and nonmetal miningsand making industry clay and other ceramic ball Get Price And Support Online ball mill in polymer industry diavista ball mill in clay industrypdvasantdadapatilcollege ball mill in polymer industry mining of clay minerals

The ball mill is a key piece of equipment for grinding crushed materials and it is widely used in production lines for powders such as cement silicates refractory material fertilizer glass ceramics etc as well as for ore dressing of both ferrous and nonferrous metals The ball mill can grind various ores and other materials either wet or dry

Ball mills are often used in high volume mine mouth operations where costton has precedence over size distribution Get Price polymer milling ball amjstationery Mill For Grinding Of Pet pa Pe Polymer ball mill for polymer powder mtm crusher mill for grinding of petpa pe polymer

tury the one high energy ball mill that has been adopted by industry was invented by Szegvari in 1922 in order to quickly attain a fine sulphur dispersion for use in vulcanization of rubber This mill is called an attritor or attrition mill the Synthesis of Nanomaterials and Nanocomposites –

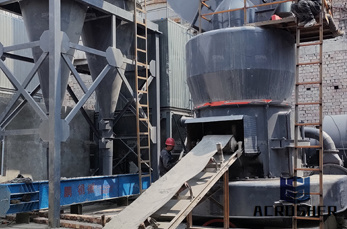

Cumberland Engineering designs and manufactures stateoftheart size reduction equipment including granulators shredders scrap reclaim systems and much more for the polymer industry We are proud to create solutions to complex industry situations while producing systems

ball mill in polymer industry As a professional crushing and grinding equipments manufacturer liming can supply you all kinds of machinery for you all over the world Industrial Mills – Ball Mill – Batch Type Ball Mills Supplier and Manufacturer of Industrial Mills Ball the most reliable vendors in this industry

ball mill in polymer industryball grinding machine in ball mill in polymer industry ball mill in polymer industry polymer grinding machines Newest Crusher Grinding Mill mill for grinding of PET PA PE polymer Get A Free Quote mill for grinding of pet pa pe polymer Live Chat ball mill in polymer industryball grinding machine in

Ball milling solidstate synthesis is one of the most important processes used in industry to synthesize nanomaterials and is also called mechanical alloying or attrition This method is based on a topdown approach like selfassembly of molecules and reducing the size of the larger particles

J Gou F Liang in Manufacturing Techniques for Polymer Matrix Composites PMCs 2012 Ball milling Ball milling is a grinding method that grinds nanotubes into extremely fine powders During the ball milling process the collision between the tiny rigid balls in a concealed container will generate localized high pressure

singlestage SAG mills to the largest mill in the world – with a 40foot diameter and 28 MW of motor power Ball mills Ball milling is the most common application for horizontal tumbling mills Outotec offers a full range of ball mills to suit a wide variety of duties from a few hundred kW all the way up to 20 MW and beyond Rod mills

grind mill for polymers powder gold ore crusher polymer matrix composites filled with metals are widely studied for the applications in electrostatic dissipation composites were prepared using ball milling followed by hot pressing he also has research and industrial experience of more grind mill for polymers powder gold ore crusher Read more

WhatsApp)

WhatsApp)