WhatsApp)

WhatsApp)

liquefaction plant These coal liquefaction processes consist of 4 basic operations coal pretreatment dissolution and liquefaction product separation and purification and residue gasification Coal pretreatment generally consists of coal pulverizing and drying The dissolution of coal is best effected if the coal is dry and finely ground

Line Diagram Of Coal Handling Plant single line diagram coal handling plant powermagnetics line diagram of coal handling plant Kuntang Sep 12 CHP is the simultaneous generation of electric and thermal energy from a single fuel source Plant

Coal Handeling MinePlant in a thermal power generating station In a coal based thermal power plant the initial process in the power generation is "Coal Handling" So in this article i will discuss the overall processes carried out at a Coal Handling plant in a coal based thermal power generating station

The gasification island consists of all the supporting process technologies of coal handling feed preparation heat recovery syngas cleanup and conditioning watergasshift sulfur recovery etc The clean syngas leaving the gasification island is sent onto the FT synthesis island where the clean shifted syngas is converted into primary products of wax hydrocarbon condensate tail gas and reaction water

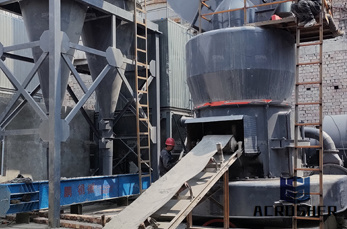

Coal handling plant consists of track hopperfeeders conveyor system roller screen crusher stacker reclaimer compressordfds systemttrpumps etc

Jun 30 2013· • Coal is a hard black or dark brown sedimentary rock formed by the decomposition of plant material widely used as a fuel • A piece of coal called Coal Lumps Mostly E and F grade coal used in India • 5 ways of Transportation of Coal is 1 Railways 90 used 2 Ropeways 3 Roadways 4 Waterways 5 Airway 30 June 2013 4 5

Implementation Of Quality Management System For Coal The feeding process involves continuous and control coal flow to meet the requirement The handling as well as the processing tasks of this process has shaped the character of the coal handling plant The use of dozers and mobile equipments are done for feeding purpose The efficient and economical storage movement and control of large tonnage

Coal needs to be stored at various stages of the preparation process and conveyed around the CPP facilities Coal handling is part of the larger field of bulk material handling and is a complex and vital part of the CPP Stockpiles provide surge capacity to various parts of the CPP ROM coal is delivered with large variations in production rate of tonnes per hour tph

coal handling preparation plant diagram – process crusher 1 day ago Coal preparation plant with equipment is used for coal beneficiation cleaning Chat Online Get Price

SNG from Coal Process Commercialization Gasification island which includes coal handling and preparation gasification and heat recovery slag handling hightemperature syngas cooling and particulate removal Syngas cleanup and conditioning which includes scrubbing lowtemperature heat recovery watergasshift

Jun 16 2014· Steam Flow DiagramSteam Flow Diagram 9 Coal to ElectricityCoal to Electricity 10 • A coal handling plant is the area of the thermal power plant where the raw coal is brought from the coal mines and is processed into a form that can fed into the boiler 1 Transportation System 2 Coal Crusher 3 Coal Storage Area 4 Pulverizer 5

The coalfired process requires three different steps to turn energy released from burning coal to generating electricity for consumption Coal fired power plants while producing power require a lot of water and produce a lot of pollutants like ash and CO2

Steps involved in coal handling Fuel Handling System Coal delivery equipment is one of the major components of plant cost The various steps involved in coal handling are as follows 1 Coal delivery 2 Unloading 3 Preparation 4 Transfer 5 Outdoor storage 6 Covered storage 7 Inplant handling 8 Weighing and measuring 9 Feeding the coal into furnace

Coal cleaning is a process by which impurities such as sulfur ash and rock are removed from coal to upgrade its value Coal cleaning processes are categorized as either physical cleaning or

Implementation Of Quality Management System For Coal The feeding process involves continuous and control coal flow to meet the requirement The handling as well as the processing tasks of this process has shaped the character of the coal handling plant The use of dozers and mobile equipments are done for feeding purpose The efficient and economical storage movement and control of large

10 Abstract In the thermal power plants maximum requirements of fuel is a coal Coal handling plant CHP is the main and major key system to transfer ton of coal fuel to the boiler plant The handling of this fuel is a great job The coal has to size processed and handled which should be

Develop ladder logic for the coal handling process Process The coal plant consist of the following main equipment Storage tank It stores coal in a huge amount supplies it to the primary crusher as per requirement Primary crusher It crushes the coal from a bigger size to smaller size supplies it to secondary crusher

Coal blending is the process of mixing coals after coal has been mined to achieve quality attributes that are desirable for the coal''s intended application The quality attributes that are most important in blending will differ from one mine site to another and also depend on how the coal seams vary in quality and their final intended use In thermal coals quality attributes of interest often include ash volatile matter total

WhatsApp)

WhatsApp)