WhatsApp)

WhatsApp)

In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rob mill ball mills, the ore in order to liberate the minerals. In ...

めまれている· Intro: Make a Ball Mill in 5 Minutes This is for all the pyro nuts that I came across on Instructables. This can be used to grind chemicals to a very fine grain ... Step 1: What You Need You need 1. A rugged container (You can use ...

(grinding media, slurry, empty ... running a small ball charge in a ball mill. An internal cascading effect reduces ... » Learn More Slurry density effects on ball milling in a laboratory ball mill ... leaving a cylinder of empty volume » ...

How to Use a Ball Mill Safely and Effectively I have some lump charcoal that just came out of my retort after I cooked it, and I want to turn it into airfloat charcoal. Or, the directions say to ball mill my rocket fuel for an hour. An article ...

A ball mill can grind and homogenize small sample volumes down to the nano range. The Emax is an entirely new type of ball mill for high energy input. Ball Mills Cutting Mills Knife Mills Sieve Shakers Disc Mills Sample Dividers ...

Quick and Easy Black Powder Ball Mill Skylighter Let''s start with the assumption that a beginner pyro hobbyist needs a relatively small ball mill, ... the mill turns the jar at ... Loading and running the ball mill ...

3. CASE STUDY A mio t/a cement plant is having a closed circuit ball mill for cement grinding: The mill has been operating with satisfactory performance interms of system availability and output, however power ...

1. Introduction The ball size is one of the critical factors for determining the mill performance of ball mills. It is well known that larger balls are needed for the effective breakage of largesize particles, whereas smaller balls are more ...

Modern Mining The Gold Rush Chronicles This ore is then loaded into small cars running on narrowgauge rails and is carried ... The Ball Mill ~ The crushed ore is now put into a ball mill, which is a huge ...

Allis Chalmers Svedala ball mill, 13'' diameter x 21'' long, rubberlined mill, with SiemensAllis 2,000 HP, 4000 volt, 200 RPM synchronous motor, Eaton airflex clutch. Includes trommel discharge, ball mill rejects conveyor, lube system ...

The proportion of the added size ball mill to be determined based on the size of the diameter of the ball mill, ore hardness, ball mill feed ore particle size, ball hardness ( quality ), ball speed and other factors. When the mill by the ...

Quick and Easy Black Powder Ball Mill How to optimize a 6 pound ball mill to safely and effectively ball mill homemade black powder. needs a relatively small ball mill, running the ball mill Chat Online

These notes are based on observations made while on a recent trip through the West, for the purpose of studying the practical operation of the ballmill. The writer takes this opportunity to express his thanks for courtesies extended at ...

Page 237 Table 1: Design Specifications SAG Mill Feed rate, Uh Feed F mm 80'' Average power, kW Ball charge, % Total charge, % Speed, % critical T mm kWh/t Ball Mills F mm Power, kW Ball charge, % Ball size, mm Speed ...

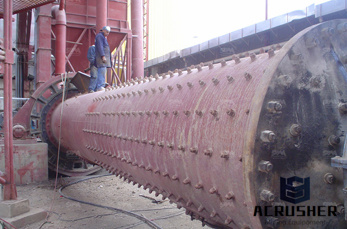

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc. as well as for ore dressing of ...

BOND BICO BALL MILL The Bond Ball Mill is a small universal laboratory mill used in calculating the grindability of all ores. GRINDABILITY IS THE NUMBER OF NET GRAMS OF SCREEN UNDERSIZE PRODUCED PER

ball nose end mill for cement and lime plant new Batch Ball Mill/Cement Ball Mill/Slag Mill you can get the Ball Mill,Lime Kiln,Batch Ball Milling ... advantages of vrm over ball mill machine cement mill type. Get Price Online

Ball Charge Permeability and Retention Time (See also section on Grinding Media) The mill ball charge is the major factor in loss of material head or resistance to material flow in the mill. Big balls have a low specific ...

めまれている· Let''s start with the assumption that a beginner pyro hobbyist needs a relatively small ball mill, that they either don''t know how to or don''t want to make one for themselves, and that they want that mill to be affordable. If I was back ...

16 PLATINUM IN TRANSFORMATION So, variation in total ball angle can be detected and linked to grinding efficiency and charge expansion. This could help the operator to make the right decision and keep the mill running at the ...

Ballmill Design Power Draw EduMine Online Tool Notes on Ball Mill Design Power Draw. Power Draw is steady running power requirement ignoring drivetrain losses and startup loads. Power Draw is reduced for Read More

PATTERSON Industries Canada "The Process Equipment People" designs, engineers and manufactures Batch Continuous type Ball Pebble Mills mainly for the Coatings, Minerals and Metal Powder ...

Planetary Ball MillS 4 applications RETSCH Planetary Ball Mills pulverize and mix soft, mediumhard to extremely hard, brittle and fibrous materials. They are suitable for both dry and wet grinding. These versatile mills are used ...

Many authors have highlighted in previously published papers that the ore breakage is closely linked to the ball charge motion. It is well known that ball milling efficiency varies during the lifetime of the shell liner. For instance, the mill ...

WhatsApp)

WhatsApp)