WhatsApp)

WhatsApp)

It is difficult to generalize on SAG mill ball size selection as it depends on a number of factors some of which are listed in the below checklist: Ore properties (hard/soft/bulky) Level of impact breakage in the mill (speed, lifter design ...

PDF (1044 K) Journal of Mining and Envonment K80 is the size of final product of the SAG mill. (underscreen) (µm) .... 31. Figure 2. Size analysis of SAG mill feed and underscreen for the first sample. Table 4. Get Price 11th MILL ...

Feed size effects what size is important? historically, MinetoMill has – focussed on blasting alone – generation of more fines • pass through SAG mill onto ball mill circuits • higher throughput ( 10% to 30%) • coarser grind size ...

2 | Model Predictive Control for SAG Milling in Minerals Processing Ore from primary crushers is combined with water in the mill where rotation causes the grinding media and the ore to be drawn upwards with the mill liners and ...

Project: 3923 Client: Sherwood Copper Corp Location: Kutcho Creek 4/16/2008 Equipment Specification Sheet: SAG Mill Specific Gravity tonnes/m3 Ball Mill Work Index metric P 80 88 µm Primary Grind P 80 43 µm

Model Predictive Control for SAG Milling in Minerals ... Model Predictive Control for SAG Milling in Minerals Processing | 5 Model Predictive Control on a SAG Mill and Ball Mills The solution for the SAG Mill is an adaptive ...

Feed size and blasting This contrasts with ball mills whose grinding media are generally constant with ... AG/SAG mill feed size distributions are the result of ... 2040 Ball Mills A ball mill grinds ores and other materials to a typical ...

Understanding Size Effects of SAG Mill Operation as a Pathway to Solving Feed Disturbances: Case Study using the MMG Century SAG Mill Presented by Brian Cornish October 2016 RA Pax1, B Cornish 2,3 1 RAP Innovation and ...

INCREASING SAG MILL CAPACITY AT THE COPPER MOUNTAIN MINE THROUGH THE ADDITION OF A PRECRUSHING CIRCUIT Dave Rose 1; David G. Meadows2; Mike Westendorf3 1 Global Director, Commissioning and ...

BWi on SAG ground ore. This BWi is used to adjust the SAG energy to the design T80 as noted above, and to calculate the ball mill size required. SAG hardness variability diagram: This is used to select the 80 th percentile of ore ...

2 SINGLE STAGE SAG/AG MILLING DESIGN ABSTRACT Single stage semiautogenous / autogenous (S/AG) milling has become a common design for a variety of ore types with the advantages of being comparatively low capital ...

SAG is an acronym for SemiAutogenous Grinding. SAG mills are essentially autogenous mills, but utilize grinding balls to aid in grinding like in a ball mill. A SAG mill is generally used as a primary or first stage grinding solution.

SAG MILL OPTIMIZATION USING MODEL PREDICTIVE CONTROL Gough, ANDRITZ AUTOMATION Ltd. 13700 International Place, Suite 100 Richmond, BC Canada V6V 2X8 ... ABSTRACT SemiAutogenous Grinding ...

effect of balls charge on sag mill performance . the model accounts for ball charge and load size distribution effects . with the motion of the charge (rocks ... difference between ball mill and sag mill modifying the mill feed size ...

3. SAG mill fractional total filling, J t, fractional ball filling, J b, and fractional rock charge filling, Jr, ( J r = J t − J b); 4. SAG mill total feed; 5. Oversize crusher product and primary cyclone underflow; and, 6. SAG mill fresh feed ...

Applying grindcurves to mill operation and optimisation Powella,*, van der Westhuizenb, Mainzab a University of Queensland, SMI, J K Mineral Research Centre, Brisbane, QLD 4068, Australia bCentre for Minerals ...

Choosing a SAG Mill To Achieve Design Performance John Starkey1, Principal Consulting Engineer Sami Hindstrom2, Manager, Grinding Travis Orser2, Project Manager, Grinding 1 Starkey Associates Grinding Design and ...

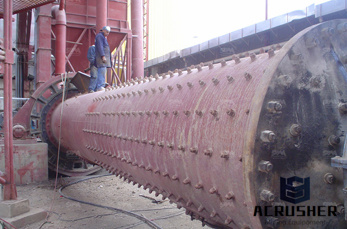

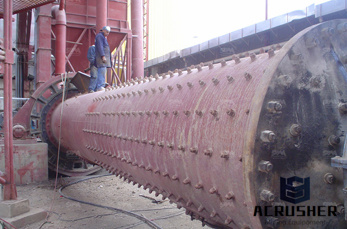

Grinding plant with SAG and tube mill for Gold/copper ore grinding in Australia. This is the world''s biggest SAG mill equipped with sliding shoe bearing arrangement and COMBIFLEX® drive system (a favourablypriced alternative ...

A typical ... crushed ore is fed into a SAG/Ball mill circuit with a median size of .... mill speed to be varied to account for operational varia ... mill feed, the weight of the ball load, the opening of. PowerGen International Burns ...

SAG MILL FEED SIZE DISTRIBUTION 11

Modelling SAG milling power and specific energy consumption including the feed percentage of intermediate size particles M. Silva, A. Casali Mining Engineering Department, Universidad de Chile, Beauchef 850, Santiago ...

depending on ball mill feed size, and some SABC (SAG/ball mill/pebble crusher) circuits operating with an efficiency of or higher on coarse feed. If the coarse feed size is reduced, the circuit efficiency will approach that ...

The standard destination for crushed pebbles has been to return them to SAG feed. However, open circuiting the SAG mill by feeding crushed pebbles directly to a ballmill circuit is often considered as a technique to increase SAG ...

Official FullText Paper (PDF): Influence of feed size on AG / SAG mill performance See all › 10 Citations See all › 7 References Influence of feed size on AG / SAG mill performance ...

WhatsApp)

WhatsApp)