WhatsApp)

WhatsApp)

The power ingesting of a grinding process is 5060 in the cement production power consumption The Vertical Roller Mill VRM reduces the power consumption for cement grinding approximately 3040 associated with other grinding mills The process variables in cement grinding process using VRM are strongly nonlinear and having large time

The Vertical Roller Mills developed by AMCL Machinery Limited are based on technical knowhow from Nihon Cement Co Ltd Japan These machines are used for substantial power saving and capacity enhancement in the field of Clinker and Rawmeal Grinding We have over two decades of experience in supply and installations of Vertical Pre Grinding

Feb 10 2016· VRM vs Ball Mill for Cement Grinding Good Days Gentlemen Anybody in this forum who have had some practicalextensive experience on Vertical Roller Mill being used for cement grinding We are planning to put up a new cement grinding plant using Vertical Roller Mill300350 – TPH and before implementing the project we would like to

measured in kWht of produced material and higher production th values vertical roller mills VRM are slowly but steadily outnumbering horizontal ball mills Vertical cement mills are able to reach production values which are significantly higher than the ones achievable with traditional ball mills in some cases up to 300 th

Vertical roller mills VRM have found applications mostly in cement grinding operations where they were used in raw meal and finish grinding stages and in power plants for coal grinding

Vertical Roller Mills VRM represent the most widely spread milling technology for raw materials in the cement industry and for many years also for clinker and slag grinding

The vertical roller mill VRM is firmly established in cement plants all over the world The biggest issues facing plants are not due to the equipment itself but more to do with how well mill maintenance is understood and how the mill is looked after following commissioning

MVR vertical roller mill with MultiDrive The highest wear occurs on the wear parts of the grinding elements as is the case with any type of vertical mill Therefore ease of replacement and regeneration is a major feature of the mill The MVR mill has a modern hydraulic system used in operation and for maintenance alike

efficient vertical roller mills VRMs led to their replacement Initially this focused on grinding coal and the cement raw materials with the adoption of vertical roller mills for cement product grinding – with its finer grinding requirements – coming more recently in the late 1990s The main reason for

vertical roller mill takes place by exposing a bed of material to a pressure sufficiently high to cause fracture of the individual particles in the bed although the majority of the particles in the bed are considerably smaller than the thickness of the bed

A more appropriate term is vertical roller mill or VRM for are two different types of vertical mills Vertical roller mills Such mills normally have int Laboratory Testing Consulting Engineering Process Equipment

At the beginning of May 2014 the Castolin Eutectic mobile intervention team performed a vertical roller mill VRM refurbishment operation in a cement plant in Switzerland Martin Trenk worldwide VRM Business Unit Manager was present onsite and explained the vertical roller mill wear problem and the Castolin Eutectic approach for a fast and longlasting repair

We have supplied vertical roller mills VRM for raw coal slag and cement grinding for several decades The vertical roller mill is well known in the cement and power plant industries as the preferred mill for grinding of raw materials It is increasingly used as a solution for efficient grinding

Feb 11 2017· Vertical Roller Mill Training by PAI This video was made by PAI which introduce the working principle of Vertical Roller mills

The order was for two vertical roller mills VRM one type LM 604 for grinding cement raw material and one LM 7044 CS the biggest Loesche VRM built for grinding cement clinker Loesche worked with Renk to develop the Compact Planetary Electrical COPE drive due to the high power requirements of the LM 7044 CS mill

The vertical roller mill VRM is well known as the preferred mill for grinding of raw materials Its grinding efficiency combined with its ability to dry grind and classify within a single unit gives it a decided advantage over other systems such as the ball mill or roll press

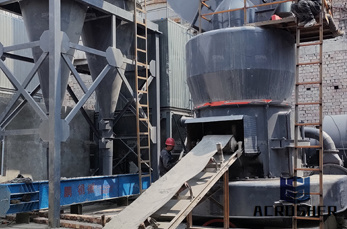

Cement Vertical roller mill VRM is mainly used to grind cement clinker into fine powder during cement production which can also be used to grind various materials such as calcite marble limestone coarse whiting talc barite and dolomite etc

WhatsApp)

WhatsApp)