WhatsApp)

WhatsApp)

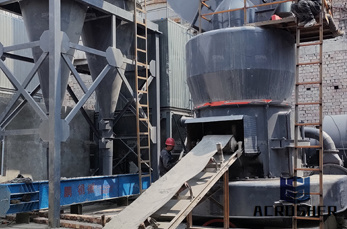

Wet Grinding And Dry Grinding Processes In Cement. Home >> Wet Grinding And Dry Grinding Processes In Cement. dry method and wet method. Cement grinding dry process ...

The effect of grinding media performance on milling and operational behaviour The product quality like particle size in a crushing or dispersing process is defined by ...

Wet grinding is often preferred by those in industrial settings because the process can have several advantages. It is less power intensive than dry grinding.

K INC. Manufacturer and exporter of wet grinding mill, micronising plant with ball mill, flocculation units, rotary kiln, industrial rotary dryer, industrial rotary ...

Abstract. By wet grinding the nature of the pulp hinders the direct contact of particles, agglomeration becomes likely only in a very late phase of the process ...

Wet milling: Wet milling with IKA''s inline machines is a safe and efficient alternative to dry grinding. Dry grinding creates a lot of dust which causes the need for ...

dry and wet process of grinding . What is Wet Grinding? wiseGEEK. ... 1 Wet process ___ grinding and mixing of the raw materials in the existence ...

03 WET GRINDING MILLS Wet grinding ball mills for the treatment of minerals, ores and other bulk materials for the wet grinding process. A large number

Basics of Grinding Fundamental Manufacturing Processes Video Series Study Guide 2 Another aspect of grinding wheels is their pore structure or density, which

Wet grinding process US A. Abstract available in . Images (1) Claims available in . Description (OCR text may contain errors) ...

Wet ultrafine grinding of ethyl cellulose by agitator bead mill To reduce the particle size, the grinding process is used and studies about the suspension ...

What Is Wet Grinding? wiseGEEK. · Wet grinding is often preferred by those in industrial settings because the process can have several advantages.

Union Process is the trusted provider of laboratory mills, wet grinding Attritors and other particle size reduction equipment.

Corn Milling, Processing and Generation of Coproducts ... wetmilling and drymilling and each process generates unique coproducts. The Corn WetMilling Process

Wet Grinding Dispersing Bühler In all industries where wet grinding and dispersion are key processes – printing inks, coatings, electronic materials or fine ...

A wet grinder can refer to either a tool for abrasive cutting of hard materials, or a food preparation appliance used especially in Indian cuisine for grinding food ...

Wet vs Dry Grinding bulkonline Forums The Powder/Bulk Portal In wet Grinding process, can go upto NANO size particles easily ... is used in " wet Grinding" for ...

Wet grinding machine method in wet grinding nanoscale powder way is the most effective and most costeffective method. It avoids the chemical method of nano powder ...

The choice between wet and dry milling is, in general, unimportant in smallscale milling but is a major technical problem when largescale milling in the ...

NETZSCHFeinmahltechnik GmbH is one of the market leader in wet grinding technology. The bundling of processrelated knowhow and the extensive machine program from ...

The Advantages of Wet Process Use in Cement . Grinding raw materials to create cement can be achieved by either using moisture, as in wet processing, or utilizing ...

process in wet grinding ... Wet grinding process incorporates horizontal media mills that increase particle size reduction. Contact us at » Learn More.

... the early cement industry used the "wet process", ... Wet grinding is performed by two distinct means: ... Simultaneous grinding of these in a rawmill is ...

A thermal model of the wet grinding process is presented. The thermal effect of the grain–workpiece interface and the shear plane between the workpiece and the chip ...

WhatsApp)

WhatsApp)