WhatsApp)

WhatsApp)

historical primitive small scale mineral processing methods iCON Gold Recovery History iCON ConcentratorsAlthough this sector presently uses primitive mineral processing methods that lose . greatly increase the product technical ...

We are counted as leading manufacturers and suppliers of preferred quality Mineral Processing Equipments. Owing to our intense perception of the customers'' demands, we are contributory in offering an innovative range of products ...

Ball mill A typical type of fine grinder is the ball mill. A slightly inclined or horizontal rotating cylinder is partially filled with balls, usually stone or metal, which grind material to the necessary fineness by friction and impact with the ...

Stone Crushing Plant May 3, 2012 ... Cement ball mill lubriion and managing ideas ... Once burning occurred, it needs over ten hours or even a couple of days to repair. .... material prior to milling and can produce between six and 10 ...

Ball Mill Grinder, Ball Mill Design, Mineral Processing Plant . We are specialized in making large and medium machineries such as Ball Mill grinder, Mineral ... gold ore ball mill processing | Clinker Grinding Mill gold ore ball mill ...

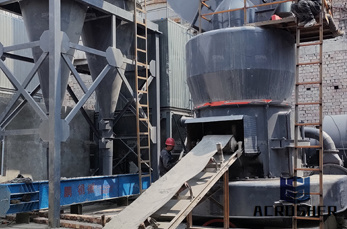

Xinhai has provided mineral processing plant services for more than 500 mines in the world. The projects spread more than 20 countries around the world with good benefits and stable operation!

Do you want to show mineral processing equipment ball mill or other products of your own company? Display your Products FREE now!

The simplest grinding circuit consists of a ball or rod mill in closed circuit with a classifier; the flow sheet is shown in Fig. 25 and the actual layout in Fig. 9. This singlestage circuit is chiefly employed for coarse grinding when a ...

Engineering consultant service, mineral processing test, mineral processing technological process, equipment selection, mineral processing plant design, construction drawing design, etc. ... Gold CIL Processing Line Gold CIL ...

cement/ball mill/ball charge design in Myanmar – Gold Ore Crusher . 2012. Ball Mill/Ball Mill Design/Mineral Ball Mill/Dry Ball Mill . MYANMAR CEMENT PLANT PROJECT MYANMAR . Flowsheet for Barite Processing;

2017/08/20· Mineral Processing Mineral Processing is the process where raw mined materials are refined to become useful components for industry. Image 1 is a picture of some of the many minerals that are mined and processed.

Do you want to show ball mill mineral processing or other products of your own company? Display your Products FREE now!

Lecture 11: Material balance in mineral processing . Key words: Material balance, ball mill, hydro cyclone, flotation. In mineral processing operations ... Mill (grinding) Wikipedia A mill is a device that breaks solid materials into ...

Ball mill is an indispensable part of mineral processing equipment According to the structure and performance of ball mill can be divided into a variety of specifications, can also be used in building materials, chemical industry ...

Mineral Processing Extractive Metallurgy explained in simple practical terms engineers and operators can understand. ... Common types of grinding mills include Ball Mills and Rod Mills. This includes all rotating mills with heavy ...

In wearresistant steel ball grinding, in the condition of the same grinding fineness, grain size more coarse, the ball mill production ability is lower; Feed particle is smaller, it has a higher production capacity. But one thing should be ...

Particle Size Distribution Effects that Should be Considered . Flotation recovery will be a strong function of the valuable mineral particle size distribution . of thumb that laboratory rod milling rather than ball milling produces a size ...

Mineral processing is a major division in the science of Extractive Metallurgy. Extractive metallurgy has been defined as the science and art of extracting metals from their ores, refining them and preparing them for use.

Ball Mill Ball mills are used for single stage fine grinding, regrinding processes. After the crushing process a ball mill is one of the most important equipment used for secondary grinding. Size reduction is carried out through Impact of ...

Mineral Ball Mill It usually adopts wet type ball mill in the mineral production. The grate and overflow type ball mills are the most universal equipment in the mineral plant. The grate type is usually used in the first segment of the two ...

Milling, sometimes also known as fine grinding, pulverising or comminution, is the process of reducing materials to a powder of fine or very fine size. It is distinct from crushing or granulation, which involves size reduction to a rock ...

In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rob mill ball mills, the ore in order to liberate the minerals. In ...

Individuals who have ever been in a processing plant in which hard material are ground into fine powder may have heard of a ball mill, but most people wonder, what is a ball mill? A ball mill is a type of device that is used for grinding ...

For that reason, you require to enjoy ball with them and be all set to transform your direction if their specialist opinion is that you''re headed down the incorrect road. Having said that, you will be fully in just your rights to reject that ...

WhatsApp)

WhatsApp)