WhatsApp)

WhatsApp)

Pig iron contains 4 to 5 percent carbon and is so hard and brittle that it''s almost useless. If you want to do anything with it, you have three options.

Barbed wire is a fencing material consisting of a metal cable with regularly spaced sharp projections. The cable usually consists of two wires twisted around each ...

163 SLAG IRON AND STEEL Blast Furnace Slag In the blast furnace, the slag floating over molten pig iron (hot metal) is flushed out in slag pot and

Production. Cast iron is made by remelting pig iron, often along with substantial quantities of iron, steel, limestone, carbon (coke) and taking various steps to ...

What are the Raw Materials needed for Refining Iron? The raw materials used to produce Pig iron in a blast furnace are iron ore, Coke, Sinter and lime stone.

The process of the extraction of iron is carried out by the following steps: Concentration of ore Calcination or Roasting of ore Reduction of ore

Chapter 73. Iron and Steel IRON AND STEEL INDUSTRY. John Masaitis. Iron is most widely found in the crust of the earth, in the form of various minerals (oxides ...

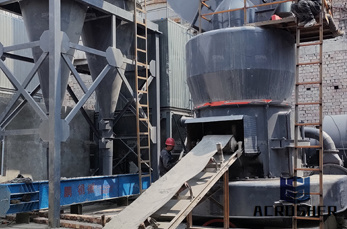

A blast furnace is a type of metallurgical furnace used for smelting to produce industrial metals, generally iron, but also others such as lead or copper.

Iron from meteorites was first used about 6000 years ago to make ornaments, weapons and tools. These days we use 20 times more iron (in the form of steel) than all ...

Pure iron is a soft, grayishwhite metal. Although iron is a common element, pure iron is almost never found in nature. The only pure iron known to exist ...

Need lime? From high quality calcitic agricultural lime to highcalcium feed lime, PB mines and markets the lime you need. See what?s on offer?

Process. Ore, limestone and carbon in the form of coke are put into the top of the blast furnace in layers. At the same time, hot air called "wind" is blown inside ...

While limestone may seem unrelated to the production of iron and steel, it actually is an essential auxiliary material that is added during the production process.

A Brief History of Iron and Steel Production. by. Professor Joseph S. Spoerl. Saint Anselm College The production of iron by humans began probably ...

An easytounderstand introduction to iron and steel, what they are, how they''re made, the various different types, and how we use them.

The iron is usually a mixture of pig iron and scrap (including risers, runners, and sprues left over from previous castings). Coke is the fuel used to heat the furnace.

Applications. Iron is the most used of all the metals, comprising 95 percent ...

Origins development of the villages, including iron ore mining Furness Railway.

Iron normally does not occur as a free element in the earth. In fact, iron was not of much value to humans until they learned how to free iron from its ...

Specific Heat of Solids Common solids like brick, cement, glass and many more and their specific heats in Imperial and SI units

Steel is an alloy of iron with about 1 percent carbon. It may also contain other elements, such as manganese. Whereas pure iron is a relatively soft ...

Figure 1. Burtonprocess barrel rolls, from Ordnance Memorandum No. 22, The Fabrication of Small Arms for the United States Service, Plate III.

The steel plant is a lean, green, recycling machine making new steel from recycled steel scrap. Enough iron and steel is recycled each year to save the nation 74% ...

Lime and Calcined Dolomite for Use in Steel Plant. Lime is a versatile compound. Various forms of lime are used in environmental, metallurgical, construction, and ...

WhatsApp)

WhatsApp)