WhatsApp)

WhatsApp)

I have 2 million ton of "granulated blast furnace slag." How can I use this slag effectively and creatively? ... Slag granulation process ...

Recent technological improvements to the slag granulation process and the ongoing development of a primary market for granulated slag as a partial substitute for ...

In a process for granulating slag, from a blast furnace or a smelting reduction plant, in which a granule/water mixture formed during the granulation is fed to a ...

Overview of blast furnace slag granulation process. Handling of blast furnace slag is an important aspect of modern blast furnace operation. Today, blast furnace slag ...

Patent US Process and . In a process for granulating slag, from a blast furnace or a smelting reduction plant, in which a granule/water mixture formed ...

Blast furnace slag granulation. View; ... chalk by heating limestone to temperatures above 950°C is the main energy consuming process. ... Blast furnace slag ...

Dry Granulation of Blast Furnace Slag for Energy Recovery Around 300 kg of liquid slag is produced as byproduct while producing one ton of hot metal in a blast ...

of Pasow, who introduced the process of air granulation, ... 233R95 Ground Granulated BlastFurnace Slag as a Cementitious Constituent in Concrete ...

Some Fundamental Aspects of the Dry Slag ... There is a growing interest in development of a dry slag granulation (DSG) process so as ... blast furnace slag ...

Environmental Technology and Resource Utilization II: Progress in Molten Blast Furnace Slag Treatment Using Dry Centrifugal Granulation Technology

Waste slag as alternative raw material in the cement ... the functioning of the granulation process as well as the blast furnace ... of blast furnace slag.

energy from the molten slag by a dry granulation process . What do we want from a ... an Prototype Plant for Heat Recovery from Blast Furnace Slag

When the metallurgical smelting process is ... the aluminates and silicates of the ore and coke ash to form a nonmetallic product called blast furnace slag.

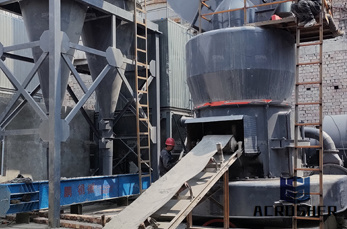

Hot Products Used for slag granulation process in blast furnace belt conveyor mtw milling machine mobile crusher vibrating screen cs cone crusher pew jaw crusher

Paper Slag Valorisation Symposium. In this paper, the dry granulation process flow and semi industrial ... valorisation are 21% for steel slags and 76% for blast ...

Converting Granulated Blast Furnace Slag into Fine ... process byproducts. This slag sand is now ... several trials were conducted at blast furnace slag granulation

Blast furnace slag granulation plant technology ... Efficient blast furnace slag granulation contributes to low ... This proven granulation process ensures economic

Granulation of titania slag has been identified ... Granulation of furnace products is well known in ... ejection of hot liquid slag. For the wet granulation process

Groundgranulated blastfurnace slag ... To cool and fragment the slag a granulation process can be applied in which molten slag is subjected to jet streams of water ...

operator blast furnace iron making equipment under apprenticeship training scheme ... cast house slag granulation process [duration 08 weeks] theory practical

THE DRY BLAST FURNACE SLAG GRANULATION AS RESOURCE AND ENERGY ECONOMY IN THE METALLURGY Elena Konchenko Donetsk National Technical University, Ukraine

The process of GGBFS is presented below The possible ... Blast furnace slag materials are generally available from ... Blast furnace slag granulation. Share ...

BLAST FURNACE SLAG GRANULATION. Slag handling is an important aspect of modern blast furnace operation. Today, blast furnace slag is ... ® slag granulation process.

The granulation of molten material, blast furnace slag for example, is accomplished by wetting the slag with a stream of water and thereafter transporting the thus ...

WhatsApp)

WhatsApp)