WhatsApp)

WhatsApp)

high efficiency iron ore mining processing equipment with Magnetite ore processing equipment list YouTube 18 Aug 2016 Magnetic Separator ore processing plantMagnetic separator is one kind High efficiency iron ore mining

Mar 23 2016· Comprehensive utilization of tailings resources not only solves environmental problems but also creates huge economic benefits In this paper fine weakly magnetic particles were extracted from iron ore beneficiation tailings and silica SiO 2 was separated and purified using a superconducting high gradient magnetic on plenty of contrast experiments SiO 2 content of the

By using the unique properties of new highenergy product permanentmagnet materials we managed to construct a roll consisting of relatively thin magnet rings with a magnetic metal ring interleaved between them The resulting magnetic field was greater than what magnetic material producers first told us would be possible to achieve

Copper Ore Beneficiation In modern industry and daily life copper has a wide range of application and demand It has an important and irreplaceable position in electric marine aviation communication petrochemicals household appliances highenergy physics metallurgy etc

Dry High Intensity Magnetic Separators DHIMS The continued improvement of high energy rare earth permanent magnetic materials has contributed to an unprecedented acceptance by several industries of rare earth permanent magnetic separators Effectively reduces the level of iron from beach sands feldspar silica sand calcium carbon

mining iron ore gold separator machine Permanent Magnetic Separator for Iron Ore Gold OrePermanent Magnetic Separator for Iron Ore Gold Ore Dressing Plant CTB Series CTB612 Large Capacity Mineral flotation separator machine flotation Ore Processing Equipment Gold Mining Spiral Classifier for Gravity Concentration And Mineral Washing Ore Dressing Plant High Vibration Strength

Magnetic separation is one purification technique that has been adapted from ore mining industries to antiscale treatment of pipe lines to seeding magnetic flocculent roll highgradient magnetic separation highintensity magnetic separation and lowintensity magnetic separation types and the high energy costs associated with

Jaykrishna Magnetics is a leading manufacturer of High Intensity Roller Type Magnetic Separator with 37 years of experience Jaykrishna Magnetics have developed costeffective highintensity highgradient permanent magnetic roller separators with the indigenous technology which has been used successfully in industrial minerals applications

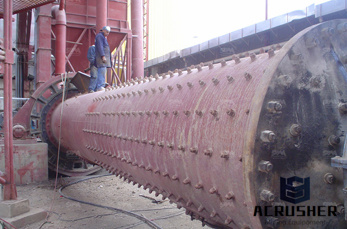

Equipment high yield magnetic separator for iron ore milling gravity or heavy media separation screening and silica froth flotation to improve the concentration of the ore and remove impurities The coal based direct reduction rotary kiln process was developed for converting iron ore

L A Lomovtsev R S Ulubabov and A S Vikul "Improvement and expansion of the use of dry magnetic concentration for iron ores a promising approach to making miningconcentration plants more efficient" in V Congress of Ore Dressers in the CIS Nations 2005 Google Scholar

The fine ore can pass through the crushing mill mining machinery again and the matrix which mixing with the fine ore can be wiped out to upgrade the purity of fine ore The production line of sand magnetic separator Energy mineral equipment sand magnetic separator for gold mining features 1 High

China Wet High Intensity Magnetic Separator manufacturers Select 2019 high quality Wet High Intensity Magnetic Separator products in best price from certified Chinese Mining Equipment manufacturers Mineral Machinery suppliers wholesalers and factory on

Eriez Wet Drum Separators Eriez'' Drum Separators are setting industry standards The newest advances in magnetic circuitry design plus over a quarter of a century of experience with solidliquid separation are combined in Eriez Wet Magnetic Drum Separators

SLon Magnetic Separator Ltd is a leading supplier producer manufacturer of high gradient magnetic separators HGMS and wet high intensity magnetic separators WHIMSIt designs develops manufactures and markets magnetic separation equipment for beneficiating weakly magnetic minerals and for purifying nonmetallic minerals

Mining Aggregate Our line of rugged separation equipment protects your belts and crushers from tramp metal while withstanding the harshest environment NonWoven Needles pins staples and other metals are stopped by a complete line of innovative metal detection and magnetic separation

It is a high energyconsuming operation and its basic principle is "more crushing less grinding" Ore beneficiation process In ore processing plant Beneficiation drafts include floatation separation gravity concentration magnetic separation and electric separation Gravity Concentration

Comprehensive utilization of tailings resources not only solves environmental problems but also creates huge economic benefits In this paper fine weakly magnetic particles were extracted from iron ore beneficiation tailings and silica SiO 2 was separated and purified using a superconducting high gradient magnetic on plenty of contrast experiments SiO 2 content of the

black friday sales JXSC specialize in the mining equipment since 1985 we manufacturing and providing full inventory of mining machine applied in the mining industry for gold diamond tin tungsten etc

leading fine iron ore magnetic separator complex impact India iron ore mining plant equipment for sale supplierIndia iron ore mining plant beneficiate fine iron ore through gravity separation and magnetic separation with high gradient The plant will be capable of processing 250 tons of fine iron ore

The highintensity magnetic field produced by the rotor requires that all ferrous metal be removed prior to the eddy current separation Pretreatment to remove ferrous metal is accomplished using a standard magnetic drum separator A production scale eddycurrent separation system is shown in Figure 3

WhatsApp)

WhatsApp)